According to statistics, more than 40% of purchase orders (PO) of manufacturing businesses are sent via fax and email, then imported manually into their system. But PO is just a part of the story. Processing all types of documents manually requires more resources, making business operations less efficient than they could be while also increasing errors and delivery delays. Manufacturing businesses understand that offering error-free services is the way to both boost profitability and keep customers, and they can achieve these things when facilitating quick, accurate order delivery through document automation.

Traditional document processing in Manufacturing – a tedious and inefficient task

Documents, anything from purchase orders, invoices, contracts, sale orders to financial records, and equipment instructions, drive many complex workflows in the manufacturing business. To keep operations on track, manufacturing businesses must ensure that documents are constantly collected and processed to be ready to use.

Most of documents in manufacturing are:

- Containing a variety of data, including structured, semi-structured, and unstructured data;

- Built into many different templates;

- Stored in diverse formats (paper, excel file, PDF, …).

Traditional document processing methods are inefficient and expensive. Source: heatonharris.com

As industry 4.0 develops, manufacturing businesses have switched from using manual paper documents to digital documents in recent years. While documents are already digitized, many companies still turn to manual methods to process them.

- Receive/send orders, invoices, and PDF documents via email;

- Extract, verify and enter post-processed data into the business management system manually;

- Keep hard copies of documents as a habit: In some cases, manufacturing businesses are forced to provide compliance documents in paper form. Besides, they also believe that keeping hard copies provides a sense of security.

Studies show that a manual worker takes up to 2 minutes to process an invoice. So, it will take a full-time employee more than 4 working days to handle 1000 invoices. Moreover, staff are forced to do monotonous, repeated tasks, thus lowering productivity and reducing operational efficiency. In addition, manual data collection and import also causes an error rate of up to 4%, which means that on average, ⅖ entered data items are incorrect. Manual data entry errors can cause many problems for manufacturing businesses, for example:

- They have negative impacts on internal operations: A simple manufacturing process can stop working due to a lack of necessary documents.

- They suffer customer or supplier satisfaction: Order processing time increases, resulting in slower order delivery to customers.

Meanwhile, manufacturing businesses can optimize operations and save resources if they apply document automation, specifically:

- PO automation increases processing speed by 80% while eliminating manual input errors.

- Invoice automation reduces 50% processing costs and increases processing speed by 3 times.

- Request for Quotes automation reduces 80% processing costs and allows businesses to efficiently respond to customer requests.

The way out? IDP!

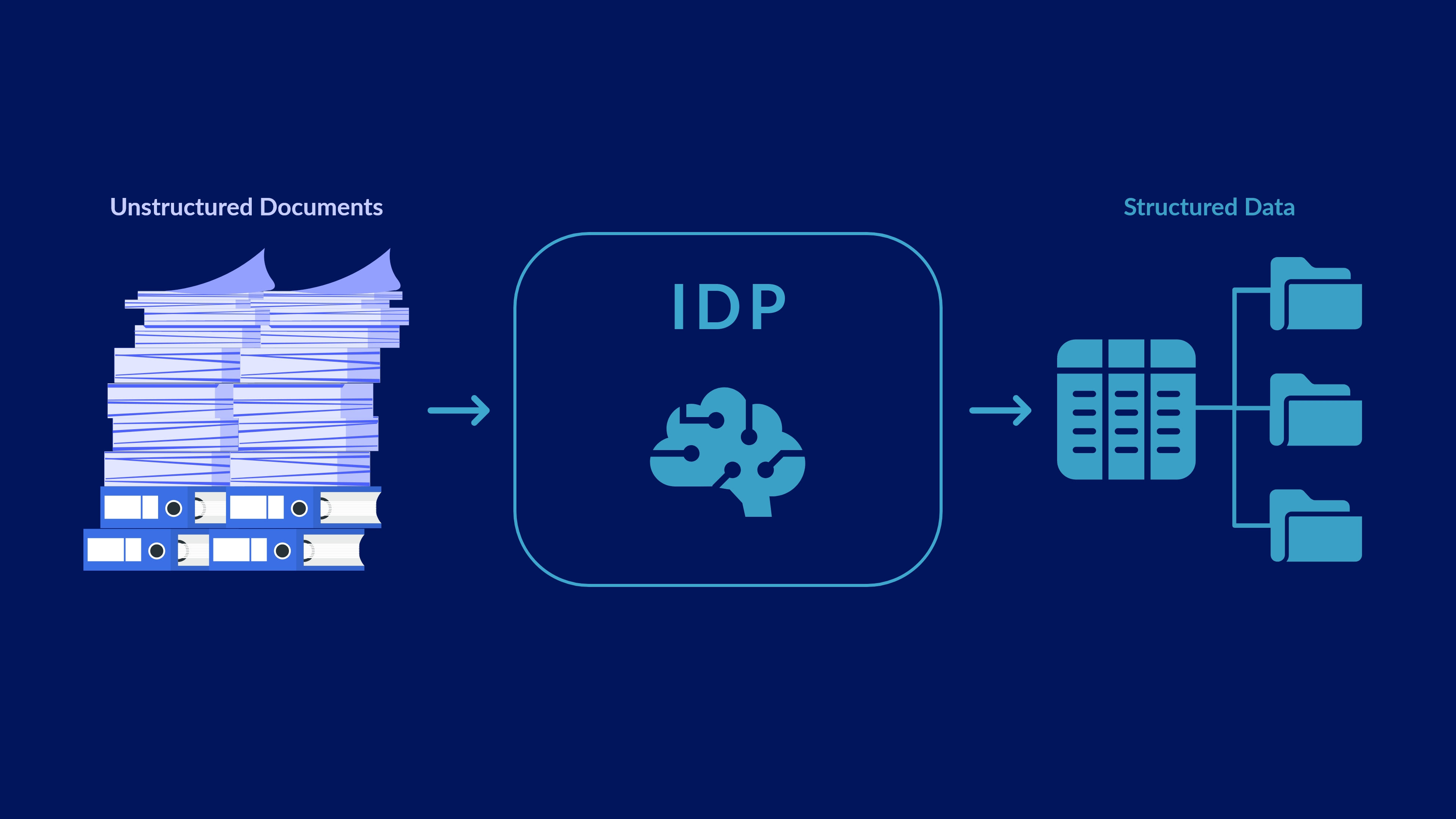

IDP (Intelligent Document Processing) collects and extracts data from semi-structured and unstructured data and converts them into structured data for use automatically.

IDP integrates and harnesses the capabilities of several technologies, including Natural Language Processing (NLP), Computer Vision, Machine Learning (ML), and OCR, to increase accuracy and efficiency in identification, classification, analysis, data extraction, and data evaluation.

IDP – an effective document processing solution. Source: assets-global.website-files.com

Traditional processing or automation software solutions are incapable of handling documents as effectively as IDP. Hence, IDP has set a new standard for data processing in manufacturing:

- IDP reduces the invoice’s processing time up to 85%, increasing data extraction speed up to 10 times. Manufacturing businesses may drastically save expenses by reducing the amount of staff for manual tasks and speeding up document processing.

- The IDP solution has a 99% accuracy rate, thereby eliminating manual mistakes and speeding up production. Therefore, manufacturing businesses may accelerate the speed of the turnaround time and better satisfy the demands of their customers and partners.

- IDP enables staff to switch from manual, repetitive tasks to more valuable projects and tasks. Manufacturing businesses’ staff no longer need to extract data from unstructured text and do manual data entry, they only occasionally need to intervene for data validation or review, thus improving productivity.

Moreover, IDP has several outstanding features that make it an excellent solution for manufacturing businesses:

IDP is more able than OCR

IDP can process complex data, including unstructured and semi-structured data, and does not require data to come in any particular template. Manufacturing businesses can benefit from IDP since they need to process a large number of complex documents with several variations, including characters, numbers, tables, images, and handwriting every day.

By integrating numerous modern technologies, IDP is capable of understanding documents. After extraction and processing, the data is ready to be saved in the company’s systems or imported into other needed systems. Furthermore, IDP processes documents with up to 99% accuracy, which is greater than OCR. Adopting IDP enables manufacturing businesses to improve processing speed, allowing enormous numbers of documents to be processed quickly and accurately.

Read more: IDP Vs OCR: What’s The Better Choice?

IDP can become smarter and smarter

Leveraging machine learning, IDP can improve its accuracy as it works. Machine Learning algorithms may self-learn depending on input data sources and fine-tune models based on specific data sources, improving accuracy over time. Manufacturing businesses can create processes with high accuracy while remaining flexible and autonomously adaptive in order to optimize operations in a short period of time without spending too much research effort.

Manufacturing businesses can minimize the time and effort required to develop high-precision processes in half. Source: metamaze.eu

IDP works well with other technologies for a comprehensive automation process

IPD and RPA in collaboration enable businesses to achieve a new level of automation – Hyperautomation. IDP is the key to unlocking RPA’s full potential, and RPA is the ideal complement to make IDP become a comprehensive automated process. RPA replaces manual staff, it collects input to IDP and delivers extracted data to required systems/places. IDP converts semi-structured and unstructured data into structured forms before extracting and validating automatically, then returning the output to RPA.

Case study: Speed up invoice processing with akaBot’s IDP

Manufacturing businesses spend a lot of money and other resources to handle a large number of input and output invoices every day, yet they face the risk of losing money due to manual errors. This forces manufacturing businesses to find a suitable technology solution to process invoices effectively. akaBot’s IDP solution is the ideal solution for manufacturing businesses. According to the G2 platform review, many users mentioned and highly appreciated akaBot’s IDP invoice processing solution.

akaBot’s integrated IDP and RPA solution enables the creation of a comprehensive automated document process. RPA bots automatically, quickly, and accurately collect invoices from email and upload them to the website. After receiving the data from RPA, IDP extracts and validates the required information and returns the results to RPA bots. Then RPA delivers the output to the required places/systems. This process runs constantly and accurately, with few interruptions. However, staff can intervene in the process to review and adjust data as needed.

akaBot’s IDP solution:

- Reducing 01 invoice processing time to2~3 seconds

- Improving accuracy to 99%

- Processing massive amounts of invoices rapidly while saving costs and other resources.

IDP is an ideal technology solution that helps manufacturing businesses process documents effectively to achieve the goal of optimizing operations, saving costs, and improving performance. In Vietnam, akaBot is the pioneer IPD solution provider, creating a premise for businesses to achieve the goal of comprehensive business automation.

akaBot has accompanied 1000+ customers in 20+ countries. A series of large enterprises such as TPbank, Daikin Vietnam, SCSK EU, VinGroup, Central Retail in Vietnam,… trust akaBot’s solution. akaBot receives several prestigious awards (Sao Khue, Vietnamese Talent, Gold Globee Winner…), and is recognized as the RPA Leader, Momentum Leader và High Performer in Mid-market in G2 2022 Summer Report.

Explore akaBot and our IDP solutions to kick start your automation goals and achieve operational excellence here.

Source:

Manual data collection: Manufacturing’s biggest problem

Document Management in Manufacturing

4 Reasons to adopt Intelligent Documents Process

Overview of Intelligent Document Processing (IDP) and its Benefits

Intelligent Document Processing for Manufacturing

Intelligent Document Processing (IDP): Unlock actionable business data faster and accelerate value

akaBot (FPT) is the operation optimization solution for enterprises based on RPA (Robotic Process Automation) platform combined with Process Mining, OCR, Intelligent Document Processing, Machine Learning, Conversational AI, etc. Serving clients in 20+ countries, across 08 domains such as Banking & Finances, Retails, IT Services, Manufacturing, Logistics…, akaBot is featured by Gartner Peer Insights, G2, and ranked as Top 6 Global RPA Platform by Software Reviews. akaBot also won the prestigious Stevie Award, The Asian Banker Award 2021, etc.

Leave us a message for free consultation!